0102030405

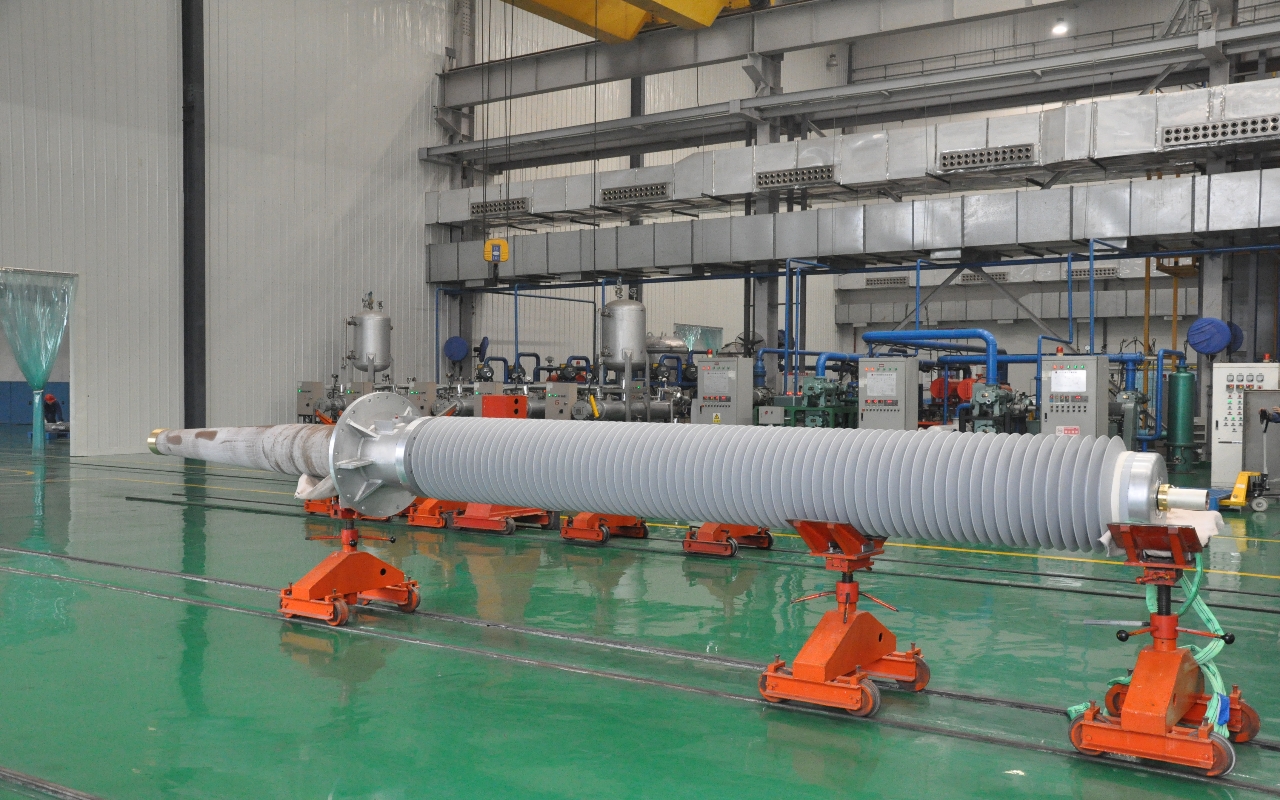

6-220kV high voltage Current Limited reactor

What is Current limiting reactor

Current limiting reactors is an inductive component which limits the switching inrush current, high-order harmonic and short-circuit fault current in the system. Current limiting reactors is made of copper or aluminum coil. The cooling methods include Air Core dry type and oil immersion type.

Generally used for distribution lines. The branch feeders from the same bus are often connected with a finite current reactor to limit the short-circuit current of the feeder and maintain the bus voltage, so as not to be too low due to the short-circuit of the feeder.

description2

How Current limiting reactors works

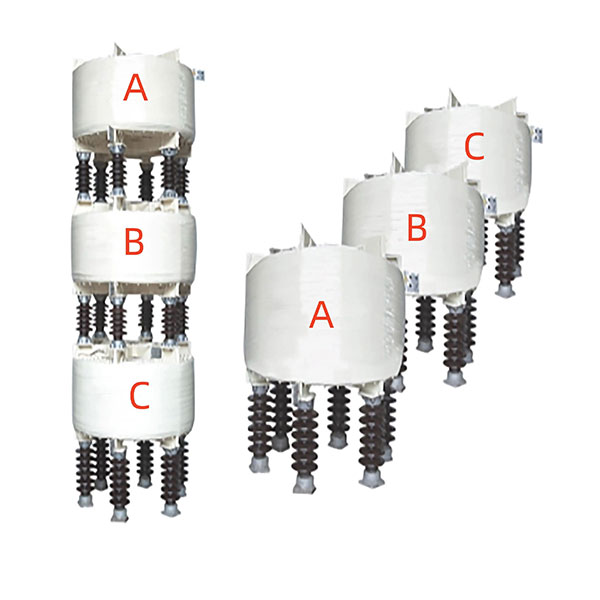

Current limiting reactors used in the power grid is essentially Air coil without magnetic conducting material. It can be arranged in three assembly forms: vertical, horizontal and zigzag. When a short circuit occurs in the power system, a large value of short circuit current will be generated. It is very difficult to keep the dynamic stability and thermal stability of electrical equipment without restriction. Therefore, in order to meet the requirements of breaking capacity of some circuit breakers, reactors are often connected in series at outgoing circuit breakers to increase short-circuit impedance and limit short-circuit current.

Due to the use of reactor, in case of short circuit, the voltage drop on Current limiting reactors is large, so it also plays a role in maintaining the bus voltage level, so that the voltage fluctuation on the bus is small, ensuring the operation stability of the user's electrical equipment on the non fault line.

Calculation and editing of capacity

The calculation formula of reactor capacity is: SN = UD% X (up / √ 3) x In, and the unit of in is Ampere.

description2

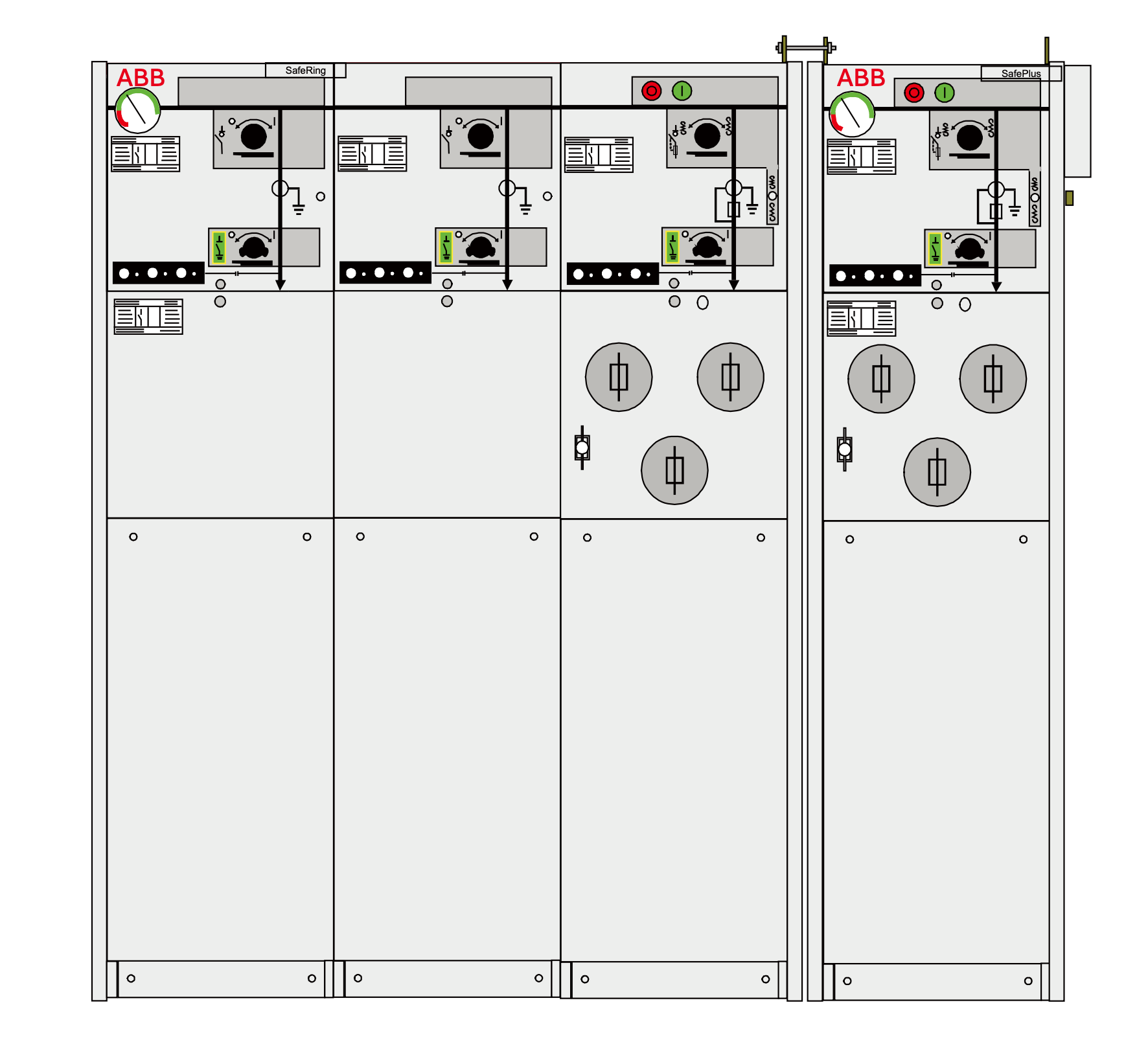

What kind of place use Current-limiting reactors

The purpose of installing Current-limiting reactors in power plants and substations is to limit the short-circuit current so that electrical appliances can be selected economically and reasonably. Reactors can be divided into line reactors, bus reactors, and transformer loop reactors according to different installation locations and functions.

(1) Line reactor. In order to use a light circuit breaker and reduce the cross section of the feeder cable, the line reactor is often connected in series to the cable feeder.

(2) Bus reactor. The bus reactor is connected in series at the section of the generator voltage bus or the low-voltage side of the main transformer. It is used to limit the short-circuit current during short-circuits inside and outside the plant. It is also called a bus section reactor. When a short circuit occurs on the line or on one bus, it can limit the short-circuit current provided by the other bus. If the requirements can be met, the installation of a reactor on each line can be omitted to save engineering investment, but it has a smaller effect of limiting short-circuit current.

(3) Transformer loop reactor. It is installed in the transformer circuit to limit the short-circuit current so that the transformer circuit can use light circuit breakers.

What are the advantages of Current limiting reactors

1. The winding is made of multiple parallel small wires and multiple strands, and the inter-turn insulation strength is high, so the loss is much lower than that of the cement reactor;

2. Adopt epoxy resin-impregnated glass fiber encapsulation, and solidify at high temperature, so it has strong integrity, light weight, low noise, high mechanical strength, and can withstand the impact of large short-circuit current

3. There are ventilation channels between the winding layers, the convection natural cooling performance is good, and the current is evenly distributed in each layer, and the dynamic and thermal stability is high;

4. The outer surface of the reactor is coated with a special anti-ultraviolet weather-resistant resin coating, which can withstand the harsh weather conditions outdoors, and can be used indoors and outdoors.

description2