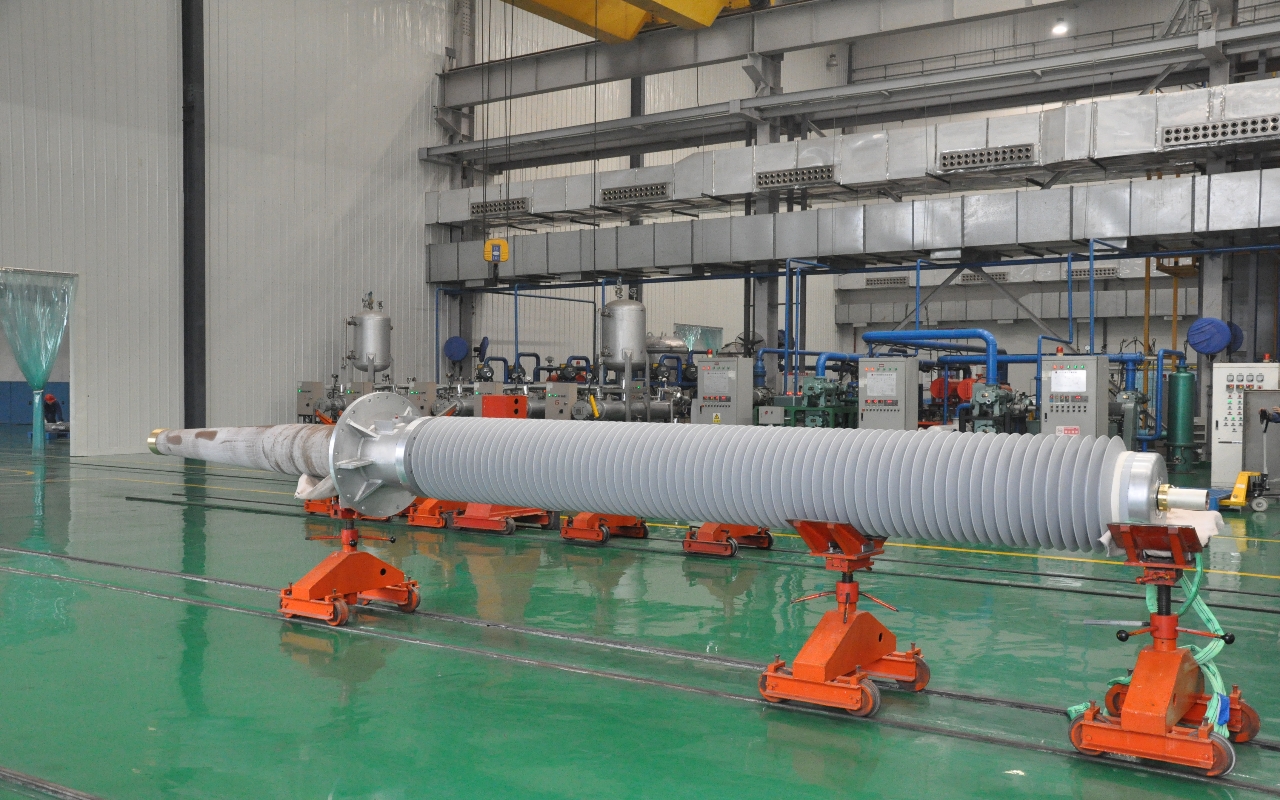

6-35kV Dry type transformer

Dry-type transformer

The SC (B) series 6-35KV epoxy resin dry-type transformer is a new generation of energy-saving products. This series of distribution transformer products are used in special occasions where the transformer voltage is directly changed from 6-35KV power grid to 400V distribution, which can reduce the 6-35KV transmission and transformation links, and significantly reduce operation and maintenance costs. The 6-35KV level non excitation voltage regulating distribution transformer product has passed the appraisal and is established as a high-tech product. The product has the advantages of low loss, good flame retardancy, strong short-circuit resistance, small size, low noise, good lightning and electric shock resistance, and uniform temperature distribution. Moreover, due to the fact that epoxy resin dry-type transformers do not use transformer oil, they will not produce oil pollution and have no explosion risk. The product can be widely used as a distribution transformer for urban power system renovation, as well as for various occasions such as high-rise buildings, airports, stations, ports, subways, etc. that have strict and special requirements for fire protection and environmental protection.

Product structure:

The epoxy resin dry-type transformer mainly consists of transformer core, transformer winding, transformer insulation, transformer lead, transformer cooling device, and temperature measurement device. The coil of the distribution transformer is wound on a high-precision winding machine, and the low-voltage winding adopts a foil winding structure. The larger capacity transformer has a ventilation duct, and after winding, it is vacuum dried. The pouring and solidification process strictly follows the process requirements to ensure that there are no bubbles or cavities inside the coil, and the transformer product achieves high-quality operation.

Core:

This series of distribution transformers selects high-quality and high magnetic grain oriented cold-rolled silicon steel sheets as the iron core, and adopts advanced silicon steel sheet cutting lines, 45 ° fully inclined seam stepped stacking sheets. The core column adopts advanced technologies such as F-grade weft free belt binding and iron yoke non punching pull plate fixation. The surface of the iron core is coated with epoxy resin to reduce the impact of magnetic leakage, effectively improve the magnetic circuit distribution, and reduce the noise, no-load loss, and no-load current of the iron core, This greatly improves the appearance quality of distribution transformer products.

High voltage winding:

The high-voltage winding adopts a segmented and layered structure, greatly reducing the interlayer voltage of the winding. It is formed by vacuum casting with epoxy resin filled with fillers, reducing local discharge inside the winding and improving the electrical performance of the coil. The interlayer of the distribution transformer winding is made of DMD epoxy resin pre impregnated fabric to increase the withstand voltage strength. The surface of the winding is filled with fiberglass mesh fabric to enhance the mechanical strength of the coil and improve the short circuit resistance of the distribution transformer product. The coil will never crack.

Low voltage winding:

The low-voltage winding adopts a foil structure, and the coil adopts an axial cooling air duct to enhance heat dissipation capacity. The interlayer of the low-voltage winding of the distribution transformer is made of DMD epoxy resin pre impregnated fabric, and the end is sealed with epoxy resin, forming an overall fixed connection.

Product features

1. Flame retardant, epoxy resin as an insulation material for SCB dry-type transformers is inherently flame retardant and will not support combustion in the event of a fire.

2. Moisture proof and dust resistant, the surface of SCB dry-type transformer winding is sprayed with three proof paint, which will not affect the dry-type transformer in harsh environments such as dust and moisture.

3. Sturdy structure, the winding of SCB dry-type transformer is cast and solidified with epoxy resin, with high mechanical strength and strong short-circuit resistance.

4. Strong overload capacity, SCB dry-type transformer has an insulation level of F, high heat resistance level, and improved operating capacity beyond the rated value of the brand.

5. Convenient maintenance, SCB dry-type transformer does not require transformer oil, and can be dried by powering on after long-term shutdown.

Usage environment:

1. Altitude: ≤ 1000 meters.

2. Environmental temperature:

Maximum temperature:+40 ℃;

Minimum temperature: -40 ℃;

Maximum monthly average temperature:+30 ℃;

Maximum annual average temperature:+20 ℃;

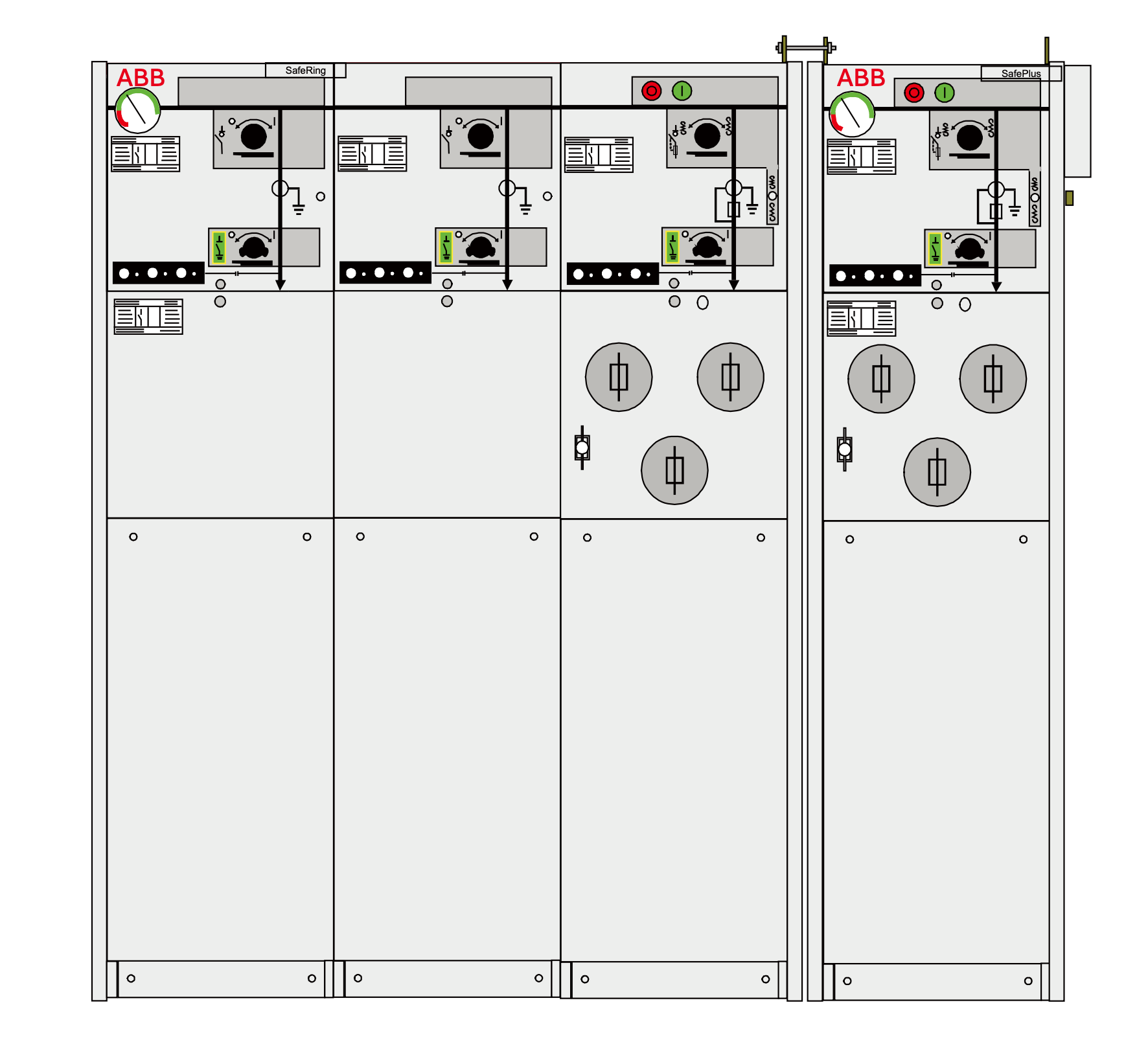

HEADING-TYPE-1

High voltage parallel capacitors are suitable for parallel connection in AC power systems with power frequency (50Hz or 60Hz) of 1kV and above. They are used to compensate for inductive reactive power, improve power factor, improve voltage quality, reduce line losses, and fully utilize the efficiency of power generation and supply equipment.

description2

HEADING-TYPE-1

High voltage parallel capacitors are suitable for parallel connection in AC power systems with power frequency (50Hz or 60Hz) of 1kV and above. They are used to compensate for inductive reactive power, improve power factor, improve voltage quality, reduce line losses, and fully utilize the efficiency of power generation and supply equipment.

description2