0102030405

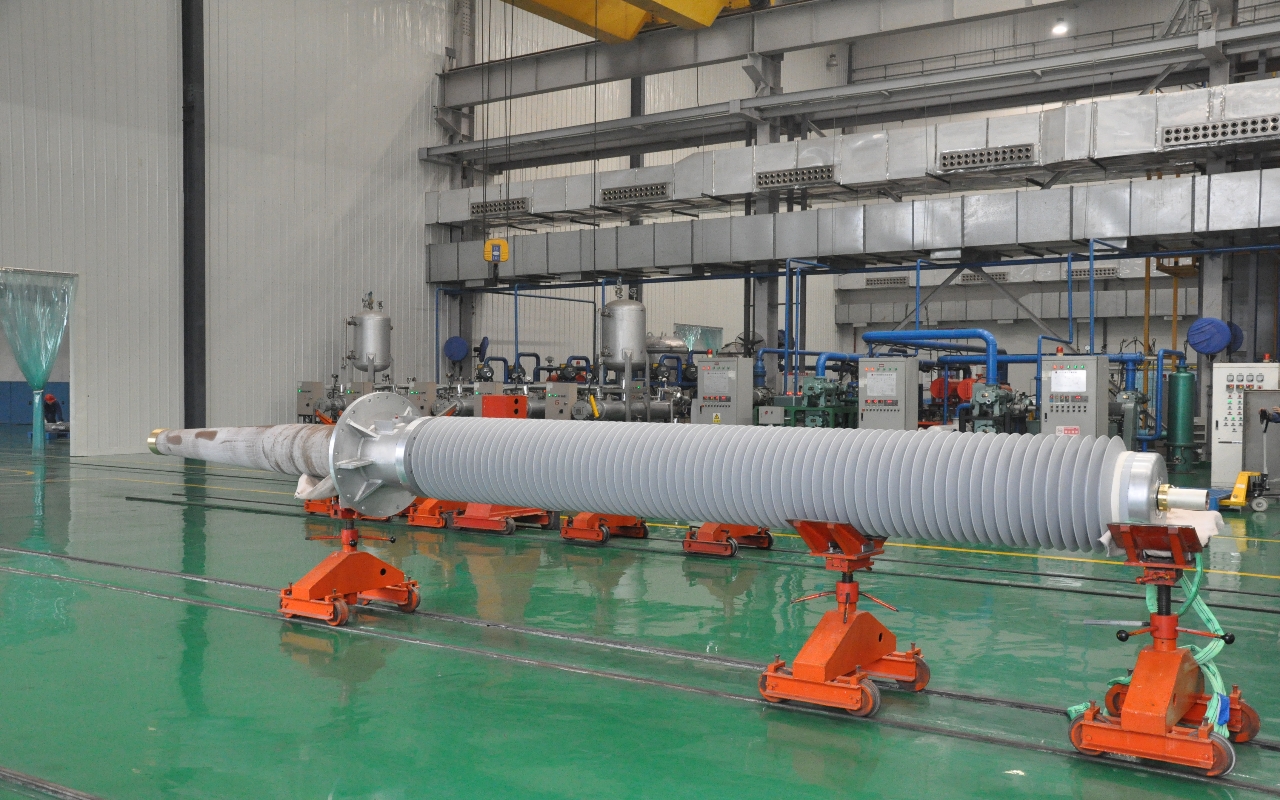

6-220kV High voltage Disconnector

Disconnector

GW4-40.5, 72.5, 126, 145D (W) type isolation relationship three-phase AC frequency 50Hz outdoor high-voltage transmission equipment is used to disconnect or connect high-voltage lines without load, in order to replace high-voltage lines, change operation mode, and implement safe electrical isolation for high-voltage electrical equipment such as busbars and circuit breakers for maintenance.

This product is a double column horizontal fracture center opening type, which can be equipped with grounding switches on either side or both sides. The isolation switch adopts CS14G or CS11 manual operation mechanism or CJ2 motor operation mechanism for three-pole linkage operation; The grounding switch adopts CS14G, CS17G or CS17D manual operating mechanisms for three-pole linkage operation.

Environmental conditions for use

Environmental temperature: -40 ° C~+40 ° C

● Altitude: not exceeding 2000m

Wind speed: not exceeding 34m/s

● Ice thickness: not exceeding 10mm

Earthquake intensity: not exceeding 8 degrees

● Air pollution level: Level III or IV or below

● Sunshine radiation level: 1000W/m2 (sunny noon)

The entire conductive circuit, except for the sliding contact at the fracture, has fixed connections between other conductors such as the outlet end, contact head, and between the contact finger and conductive arm, with low contact resistance and reliable operation.

The conductive arm is made of rectangular aluminum alloy tubes, which have high strength, light weight, large heat dissipation area, and good anti-corrosion performance.

Made of special copper alloy to create a self operated contact finger. By relying on the elastic force of the contact finger itself to clamp the contact, the contact finger spring has been eliminated, eliminating the vicious cycle of reduced contact clamping force, increased contact resistance, and intensified contact heating caused by spring corrosion, shunt heating, and annealing. The contact is bent from copper plate and has a large connection area with the conductive arm. During the opening and closing process, the friction stroke between the contact and the finger is short, and the operating force is small.

The rotating part of the isolation switch is designed to be maintenance free. The rotating seat is designed as a sealed structure,

Water vapor, dust, and harmful gases cannot enter, preventing the loss and solidification of molybdenum disulfide lithium based lubricating grease inside the bearing; The bearing seat is equipped with thrust ball bearings and radial ball bearings inside, which bear the gravity and horizontal force of the isolation switch through these two special bearings, so that the operating torque of the isolation switch will not increase after long-term operation.

description2